Benefits of Calcium Sulfate Raised Floor

1. They have high strength, so they can be installed in rooms with high traffic of people.

2. In the case of a non-separable design, inspection hatches can be installed at any point. The tongue-and-groove joint reinforces the joints of the plates, so heavy equipment can be installed on them. Tactile seams are not felt.

3. Installation does not require serious preparation of the rough screed.

4. The soundproofing system of the panel (calcium sulphate) absorbs noise up to 64db.

5. It is possible to install any communications under the raised floors (electrical, plumbing, weak point, fire extinguishing system, etc.).

6. Calcium sulphate raised floors consist of gypsum and cellulose. This is a safe material for health, so it is allowed to be laid in children's educational institutions.

7. PVC or porcelain tile raised floor is easy to maintain. It can be washed with any detergent.

8. Collapsible floors can be dismantled locally, there is no need to change the entire structure.

Where applicable

Raised floor slabs made of calcium sulfate are characterized by high density and high bearing capacity, so they are used:

1. In large open-plan offices where massive equipment is expected to be installed.

2. In server rooms and data centers.

3. In rooms with high traffic. For example, in shopping, business centers and office buildings.

4. In industrial premises.

It is possible to use calcium sulfate plates in such conditions due to their high strength. For example, panels from Jansen comply with deflection class A (up to 2.5 mm), and the fracture load reaches up to 1200 kg per point.

The main features of the material

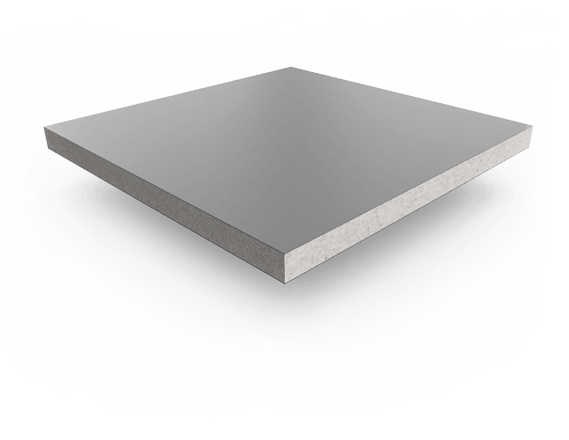

◉ Calcium sulfate is made from a mixture of gypsum and cellulose fibers. Panels from different manufacturers may vary in density, which depends on the properties of these materials. Gypsum and cellulose are environmentally friendly materials that do not pose a health hazard and are durable

Distinctive features:

1. The thickness of panels can vary from 28mm to 40mm.

2. Standard size is 600 x 600 mm.

3. The panel can be reinforced on the underside with 0.5mm metal sheet.

A variety of finishes can be used with calcium sulfate raised floor slabs: carpet tiles or carpet, LVT tiles or laminate, parquet or linoleum. Porcelain stoneware installation is also allowed, it is installed at the factory and is delivered assembled.

Characteristics

It is the technical parameters that are the main argument in favor of raised floors made of calcium sulfate. Here are the main advantages:

1. Fire hazard class. Thanks to this, the plates can be used where other materials are not suitable, but access to the underground space is required.

2. The bearing capacity can be from 1500 to 3500 kg/m2. It depends on the thickness and whether a metal sheet is used on the underside.

3. Antistatic effect. Plates do not allow the occurrence of electrical discharges on the surface. The edges are treated with PVC tape with an antistatic effect. Thanks to this, the coating can be used in switchboard or server rooms.

Among other useful properties, sound insulation can be noted. Raised floor panels made of calcium sulphate do not transmit sound well on their own, and in combination with a carpet or carpet tile finish, you can achieve the most comfortable acoustic environment in the room.